Goodyear, uno de los fabricantes de neumáticos con mayor trayectoria e historia a nivel mundial, reconoce el punto de inflexión en el que se encuentra el transporte y la movilidad. Y aunque hoy es difícil predecir cómo serán en el futuro, la compañía cree en un ecosistema impulsado por nuevas tecnologías, con experiencias de movilidad sostenible, segura e innovaciones que transformen la manera en la que nos conectamos y nos desplazamos.

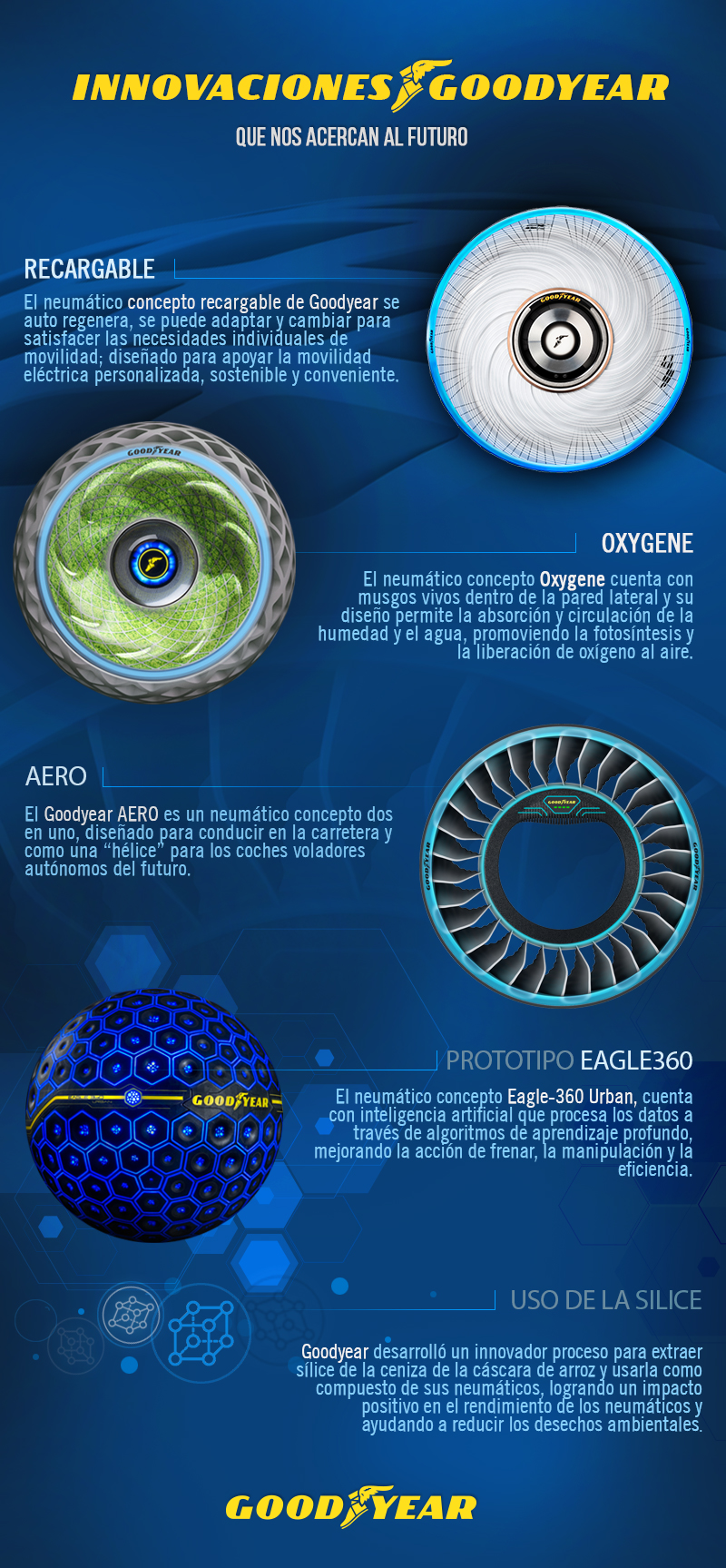

Por este motivo, y para estar a la vanguardia de los principales desafíos que se vienen, dedica tiempo en la investigación y desarrollo para crear nuevas tecnologías, materiales y compuestos innovadores, así como neumáticos concepto. En los últimos cuatro años, la marca presentó distintos modelos como:

- El revolucionario neumático recargable de Goodyear, fabricado con material biológico y reforzado con fibras inspiradas en uno de los materiales más fuertes del mundo, que tiene la capacidad de auto regenerarse, adaptarse y cambiar según las necesidades de movilidad (2020).

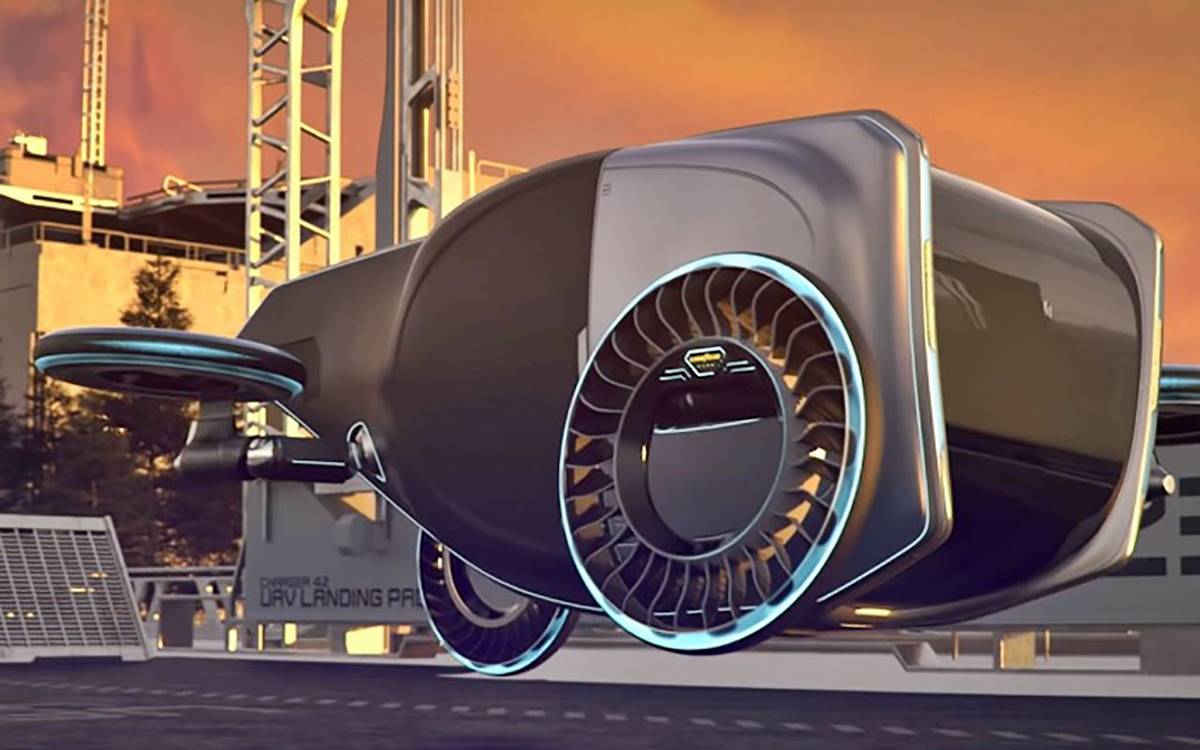

- El neumático Goodyear Aero, es un modelo para los autos voladores del futuro. Cuando se aplica al vehículo, los neumáticos también funcionan como hélices para lograr la propulsión y permitir el vuelo (2019).

- El neumático de Goodyear Oxygene propone una solución visionaria con una estructura que contiene musgos vivos que crecen dentro de la pared lateral del neumático para una movilidad urbana más limpia, conveniente, segura y sostenible. Su uso generaría prácticamente 3,000 toneladas de oxígeno y absorbería más de 4,000 toneladas de dióxido de carbono al año (2018).

- El Goodyear Eagle 360 Urban es el primer concepto de neumático en ser activado por inteligencia artificial capaz de responder a las demandas de la conducción autónoma (2017).

SÍLICE DE CENIZA DE CÁSCARA DE ARROZ

Con el objetivo de buscar fuentes de materiales alternativos que tengan un impacto positivo en el rendimiento de los neumáticos y a su vez aprovechar residuos que comúnmente son descartados, Goodyear comenzó a explotar el uso de sílice RHA.

La adición de sílice mejora la flexibilidad y elasticidad de la banda de rodamiento a temperaturas más bajas, lo que proporciona una mejor tracción y agarre. Por ese motivo este compuesto fue oficialmente incluido en la cartera de materiales de Goodyear y se utiliza en varias de sus plantas de fabricación a nivel global.

La compañía continúa trabajando en estrecha colaboración con sus proveedores para expandir aún más el uso de sílice RHA y se ha fijado el objetivo de duplicar su uso para 2021.